February 21, 2023 — In 2011, Taiwan Port Corporation won two “Public Works Gold Awards”, which are known as the Oscars in the engineering industry and symbolize the highest honor for the quality of public works in the country. Land Reclamation Project for Embankment of the Back Line” and “Kaohsiung Port Seventh Container Center Project-S1~S3 Wharf Revetment and Xinxin Land Filling Project” sponsored by Kaohsiung Branch, of which “Kaohsiung Port Seventh Container Center Project-S1 ~S3 Wharf revetment and new land reclamation project” also won the 16th Excellent Engineering Golden Safety Award of the Ministry of Labor, and the quality of public works has been recognized.

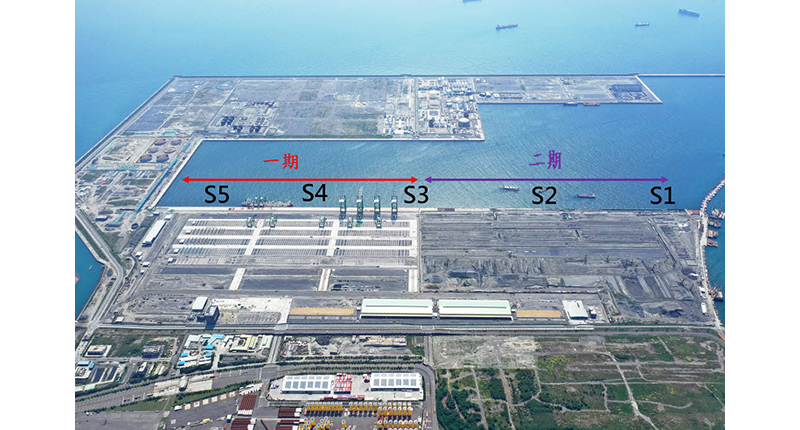

Photo above: Aerial photo of Kaohsiung Port Seventh Container Center Project – S1~S3 wharf revetment and Xinxindi reclamation project.

“Taipei Gangnan Wharf S07, S08 Bank Revetment and Rear Line Embankment Land Construction Project” is characterized by the new construction of temporary embankment and the recycling and reuse of the demolished temporary embankment materials. The new site gives priority to using the waters for boating to dredge and excavate earth for filling, which saves the project cost by approx. 13.9%, and achieved the effect of energy saving and carbon reduction; in June 2011, priority was given to completing the filling of S08-1 new land (about 7.4 hectares) and handing it over to attract investment; in June 2011, the remaining S07-1 new land (about 10.3 hectares) was completed ), in July 2011, 17.7 hectares of new land was completed ahead of schedule and handed over for operation. After completion, it will not only increase the land use and rental income of the port, but also improve the functions of the port and revitalize the overall use efficiency.

Another award-winning “Kaohsiung Port Seventh Container Center Project – S1~S3 Wharf Revetment and Xinxin Land Filling Project” is to enhance the competitiveness and sustainable development of Kaohsiung Port, fully promote the seventh container center project and divide it into two phases Construction, among which the first phase of the S4~S5 wharf revetment and new land reclamation project has been completed, and the container yards behind the S1~S3 wharf and related operating infrastructure have been constructed successively; the award-winning feature is that the new S1~S3 wharf design has a total length of 1,230m With a water depth of -18m, it is suitable for the berthing of the world’s largest 24,000 TEU container ship. In order to overcome the impact of waves and improve the static stability of the water area, according to the functional requirements of different locations of the wharf, different structural types (such as gravity type, steel pipe (plate) pile type, trestle type) are adopted in the design. type, caisson type), in which the innovative use of pressure-relief steel pipe (plate) pile structure can reduce the stress on the main pile, and at the same time use the reclaimed intercontinental first-stage embankment caisson as the anchor structure to save engineering costs, and in addition to widen the channel space, When the second port of Kaohsiung Port was first built, the Chinese pioneered the circular caisson breakwater. Among them, 13 circular caissons in the south embankment were relocated and reused as ecological submerged dikes, which enriched the ecological diversity of the port area. After completion, it can be greatly improved Kaohsiung Port’s container handling capacity strengthens Kaohsiung Port’s competitiveness in the global shipping market and continues to play the role of a container transshipment hub port.

From its establishment in 101 to 111, the Port Company has won gold medals and golden safety awards for many times. It has formulated various key points and plans for the planning, design, construction quality and safety of port projects and implemented them. Quality, environmental protection, and safety are the highest guiding principles to improve the quality of its public projects; the award has a great affirmation and encouragement to the company’s construction teams and engineering colleagues. This year, 112 also submitted a number of excellent engineering cases to participate in the competition, hoping to achieve greater success .